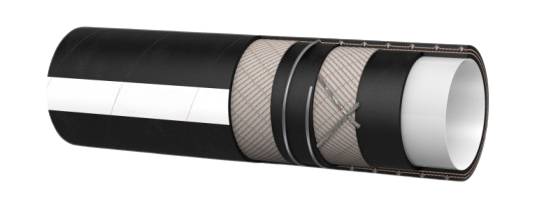

Inner Tube :

1. UPE (UHMWPE – Ultra High Molecular Weight Polyethylene), light colour, mirror-smooth. 2. Compliance: FDA Standards, D.M. 21/03/73 and following amendments, and Regulation EU n. 10/2011.

Reinforcement :

1. High strength plies of synthetic cord. 2. Embedded steel helix wire. 3. Built-in copper wires.

Cover :

EPDM rubber, black colour, antistatic (R < 10^6 Ω), resistant to abrasion, ozone and weather, smooth, cloth finish.

Industrial application :

POLYSPIR is a multipurpose hose for suction and delivery of a wide range of chemical, alcoholic and food products. Normally installed on tank trucks, unloading platforms, chemical laboratories, stationary and mobile systems in food and chemical industries.

Features :

The inner tube of the hose POLYSPIR/UPE-BN is suitable for conveying alcohol with a concentration up to 98%.

Temperature :

From -35°C to +100°C. Resistant to steam up to +130°C for a maximum time of 30 minutes.

Item Code | Wall thickness | Vacuum | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | mm | inch | mm | psi | bar | psi | bar | inch | mm | ||||

| CEW131-01 | 1/2 | 13 | 0.94 | 24 | 5.5 | 150 | 10 | 600 | 40 | -0.9 | 3.15 | 80 | 0.45 |

| CEW131-02 | 3/4 | 19 | 1.22 | 31 | 6 | 150 | 10 | 600 | 40 | -0.9 | 4.53 | 115 | 0.65 |

| CEW131-03 | 1 | 25 | 1.46 | 37 | 6 | 150 | 10 | 600 | 40 | -0.9 | 5.91 | 150 | 0.82 |

| CEW131-04 | 1 1/4 | 32 | 1.73 | 44 | 6 | 150 | 10 | 600 | 40 | -0.9 | 7.48 | 190 | 0.98 |

| CEW131-05 | 1 3/8 | 35 | 1.85 | 47 | 6 | 150 | 10 | 600 | 40 | -0.9 | 8.27 | 210 | 1.05 |

| CEW131-06 | 1 1/2 | 38 | 2.01 | 51 | 6.5 | 150 | 10 | 600 | 40 | -0.9 | 9.06 | 230 | 1.25 |

| CEW131-07 | 1 37/64 | 40 | 2.09 | 53 | 6.5 | 150 | 10 | 600 | 40 | -0.9 | 9.45 | 240 | 1.3 |

| CEW131-08 | 1 31/32 | 50 | 2.52 | 64 | 7 | 150 | 10 | 600 | 40 | -0.9 | 11.81 | 300 | 1.84 |

| CEW131-09 | 1 31/32 | 50 | 2.6 | 66 | 8 | 150 | 10 | 600 | 40 | -0.9 | 11.81 | 300 | 2 |

| CEW131-10 | 2 1/2 | 63,5 | 3.13 | 79.5 | 8 | 150 | 10 | 600 | 40 | -0.9 | 15.35 | 390 | 2.55 |

| CEW131-11 | 2 3/4 | 70 | 3.39 | 86 | 8 | 150 | 10 | 600 | 40 | -0.9 | 16.54 | 420 | 2.7 |

| CEW131-12 | 2 61/64 | 75 | 3.58 | 91 | 8 | 150 | 10 | 600 | 40 | -0.9 | 18.9 | 480 | 3 |

| CEW131-13 | 3 5/32 | 80 | 3.78 | 96 | 8 | 150 | 10 | 600 | 40 | -0.9 | 18.9 | 480 | 3.15 |

| CEW131-14 | 3 15/16 | 100 | 4.65 | 118 | 9 | 150 | 10 | 600 | 40 | -0.9 | 23.62 | 600 | 4.9 |

| CEW131-15 | 4 | 102 | 4.72 | 120 | 9 | 150 | 10 | 600 | 40 | -0.9 | 23.62 | 600 | 4.92 |