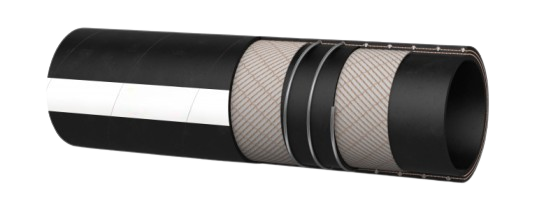

Inner Tube :

EPM rubber (code 660N), antistatic (R < 10^6 Ω), black colour, smooth, free from nitrosamines.

Reinforcement :

1. High strength plies of synthetic cord. 2. Embedded steel helix wire. 3. Built-in copper wires on request.

Cover :

EPDM rubber (code 104N), black colour, antistatic (R < 10^6 Ω), resistant to abrasion, ozone and weather, smooth, cloth finish.

Industrial application :

MANICHEM/SD-EPM is a suction and delivery hose for conveying chemicals with high concentration.

Features :

Why should you prefer EPM to EPDM? -EPM provides higher resistance to oxidizing acids. -EPM provides a better chemical resistance to high temperatures: when conveying acetone, alcohol, ester and acids, it is more resistant to the fluids thanks to its impermeable inner tube and compact structure. -EPM offers better compression set values, thus making the assembly with fittings safer for chemical applications.

Note :

Safety factors: 1. ≥ 4 times working pressure up to DN 75 mm. 2. ≥ 3 times working pressure over DN 75 mm. Other sizes and colours are available upon request.

Temperature :

Resistance to steam up to +130°C for max. 30 minutes.

Item Code | Wall thickness | Vacuum | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | mm | inch | mm | psi | bar | psi | bar | inch | mm | ||||

| CEW134-01 | 3/4 | 19 | 1.22 | 31 | 6 | 240 | 16 | 960 | 64 | -0.9 | 4.92 | 125 | 0.7 |

| CEW134-02 | 1 | 25 | 1.46 | 37 | 6 | 240 | 16 | 960 | 64 | -0.9 | 5.91 | 150 | 0.8 |

| CEW134-03 | 1 1/4 | 32 | 1.73 | 44 | 6 | 240 | 16 | 960 | 64 | -0.9 | 6.89 | 175 | 1 |

| CEW134-04 | 1 1/2 | 38 | 2.01 | 51 | 6.5 | 240 | 16 | 960 | 64 | -0.9 | 8.86 | 225 | 1.26 |

| CEW134-05 | 1 31/32 | 50 | 2.6 | 66 | 8 | 240 | 16 | 960 | 64 | -0.9 | 10.83 | 275 | 2.1 |

| CEW134-06 | 2 | 51 | 2.64 | 67 | 8 | 240 | 16 | 960 | 64 | -0.9 | 10.83 | 275 | 2.15 |

| CEW134-07 | 2 1/2 | 63.5 | 3.13 | 79.5 | 8 | 240 | 16 | 960 | 64 | -0.9 | 11.81 | 300 | 2.6 |

| CEW134-08 | 2 61/64 | 75 | 3.58 | 91 | 8 | 240 | 16 | 960 | 64 | -0.8 | 13.78 | 350 | 3.05 |

| CEW134-09 | 3 | 76 | 3.62 | 92 | 8 | 240 | 16 | 720 | 48 | -0.8 | 13.78 | 350 | 3.1 |

| CEW134-10 | 3 15/16 | 100 | 4.65 | 118 | 9 | 240 | 16 | 720 | 48 | -0.8 | 17.72 | 450 | 4.95 |

| CEW134-11 | 4 | 102 | 4.72 | 120 | 9 | 240 | 16 | 720 | 48 | -0.8 | 17.72 | 450 | 5 |