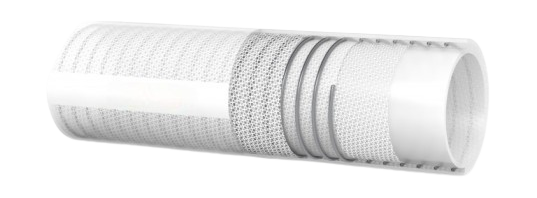

Inner Tube :

Silicone rubber, translucent (code silicone 3362PT), food and pharmaceutical quality, odourless and tasteless, smooth, glossy finish.

Reinforcement :

1. High-strength synthetic plies. 2. Embedded stainless steel helix wire.

Cover :

1. Silicone rubber, translucent (code silicone 3362PT), food and pharmaceutical quality, smooth with glossy finish. 2. It may easily be cleaned with any mild detergent.

Industrial application :

Silicone hose for suction and delivery of high purity products, foodstuff and fluids with alcohol content up to 96%. Reinforced version suitable for process applications requiring a tight bending radius and a high vacuum resistance. CLEARWAY/HD-Platinum is normally used in food, pharmaceutical and cosmetic industries.

Features :

Resistant to suction. Platinum-cured silicone cover with non-stick properties. Made in Cleanroom ISO 14644-1 Class 8. Used in aseptic environments and sanitary applications: produced with the utmost care, from the choice of high-purity ingredients to production and storing procedures. Pharma grade validation: tested in accordance with USP Class VI and EU Pharmacopoeia.

Note :

Safety factors: ≥ 3 times working pressure. Sterilization: 1. Sterilization with steam up to +135°C at 3.5 bar for max. 90 minutes. 2. Sterilization with hot air up to +200°C for max. 30 minutes. 3. Sterilizations repeated at intervals of less than 1 hour may seriously affect the mechanical features of the hose. Other sizes are available on demand.

Temperature :

-60°C up to +200°C. At a temperature of +100°C the W.P. decreases by 20%.

Item Code | Wall thickness | Vacuum | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | mm | inch | mm | psi | bar | psi | bar | inch | mm | ||||

| CEW123-01 | 3/8 | 10 | 0.87 | 22 | 6 | 145 | 10 | 435 | 30 | -0.9 | 1.97 | 50 | 0.38 |

| CEW123-02 | 1/2 | 13 | 0.98 | 25 | 6 | 145 | 10 | 435 | 30 | -0.9 | 2.05 | 52 | 0.45 |

| CEW123-03 | 5/8 | 16 | 1.14 | 29 | 6.5 | 145 | 10 | 435 | 30 | -0.9 | 2.36 | 60 | 0.53 |

| CEW123-04 | 3/4 | 19 | 1.26 | 32 | 6.5 | 145 | 10 | 435 | 30 | -0.9 | 2.6 | 66 | 0.62 |

| CEW123-05 | 1 | 25 | 1.5 | 38 | 6.5 | 145 | 10 | 435 | 30 | -0.9 | 3.39 | 86 | 0.75 |

| CEW123-06 | 1 1/4 | 32 | 1.77 | 45 | 6.5 | 145 | 10 | 435 | 30 | -0.9 | 4.33 | 110 | 0.92 |

| CEW123-07 | 1 1/2 | 38 | 2.05 | 52 | 7 | 145 | 10 | 435 | 30 | -0.9 | 5.12 | 130 | 1.25 |

| CEW123-08 | 1 31/32 | 50 | 2.52 | 64 | 7 | 145 | 10 | 435 | 30 | -0.9 | 7.88 | 200 | 1.62 |

| CEW123-09 | 2 9/16 | 65 | 3.11 | 79 | 7 | 116 | 8 | 348 | 24 | -0.9 | 9.84 | 250 | 2.22 |

| CEW123-10 | 2 61/64 | 75 | 3.5 | 89 | 7 | 116 | 8 | 348 | 24 | -0.9 | 13.78 | 350 | 2.95 |

| CEW123-11 | 3 15/16 | 100 | 4.5 | 114 | 7 | 101 | 7 | 303 | 21 | -0.9 | 19.69 | 500 | 3.62 |