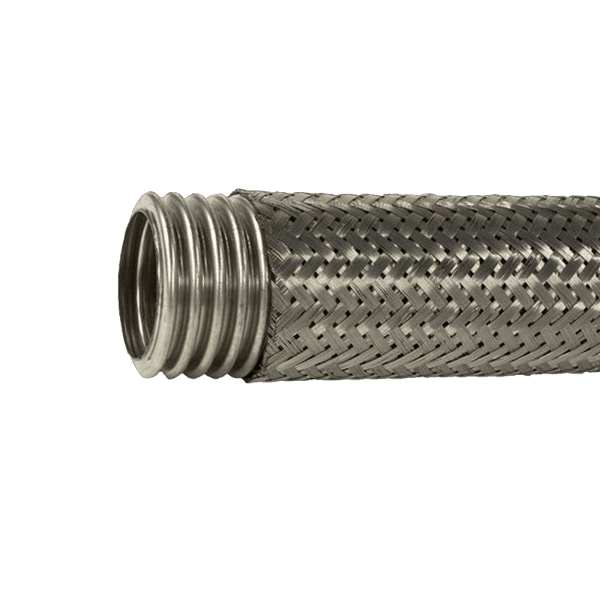

Hose Material :

Stainless steel grades 304/304L/316/316L/321

Braiding Material :

Stainless steel grades 304/304L/316/316L.

Fluid compatibility :

Oil, gasoline, LPG, toluene, benzene, petrol, alcohol, LSHS. steam, other derivatives & highly corrosive chemicals.

Industrial application :

Refineries, Chemical industries, Power plant, Steel plant & Pharmaceutical Industries, etc.

Characteristics :

Light weight and High Flexibility

Features :

These metal hoses are appropriate for use in any situation where operational circumstances require one or a combination of the following: vacuum, cryogenic, absolute leak proof, a high safety factor, extreme temperature, vibrations, high working pressure and corrosion resistance. Applicable for chemical transfer, super-heated steam, coolant lines, fuel and oil burner lines, petroleum, refrigerants, gases, poisonous media and food stuff.

Temperature :

- 200°C to 800°C for AISI 321 & 316. - 200°C to 420°C for AISI 304 & 304L.

Product Pressure :

High-Pressure

Product Construction :

Annular and Close pitch

| Nominal hose size (inch) | Item code | Braid layers | Nominal OD | Nominal ID |

Minimum centerline bend radius (mm)

|

Pressure rating at 23⁰C (kg/m)

|

Weight (kg/m) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Static | Dynamic | Max working | Max test | Nominal burst | ||||||

| 1/4 | CEW56-01 CEW56-02 CEW56-03 |

0 1 2 |

9.6 10.8 12.0 |

6.2 | 25 | 70 | 12 120 192 |

18 180 288 |

480 768 |

0.100 0.175 0.256 |

| 5/16 | CEW56-04 CEW56-05 CEW56-06 |

0 1 2 |

12.2 13.5 15.0 |

8.2 | 30 | 90 | 10 100 160 |

15 150 240 |

400 640 |

0.115 0.195 0.288 |

| 3/8 | CEW56-07 CEW56-08 CEW56-09 |

0 1 2 |

14.4 16.0 17.5 |

10.3 | 35 | 100 | 9 90 144 |

14 135 216 |

360 576 |

0.150 0.253 0.371 |

| 1/2 | CEW56-10 CEW56-11 CEW56-12 |

0 1 2 |

16.9 18.2 19.5 |

12.2 | 45 | 110 | 9 80 128 |

14 128 192 |

320 512 |

0.175 0.297 0.436 |

| 5/8 | CEW56-13 CEW56-14 CEW56-15 |

0 1 2 |

21.8 23.5 25.0 |

16.2 | 50 | 120 | 8 70 112 |

12 105 168 |

280 448 |

0.250 0.455 0.685 |

| 3/4 | CEW56-16 CEW56-17 CEW56-18 |

0 1 2 |

26.8 28.3 29.8 |

20.2 | 55 | 130 | 4 64 102 |

6 96 154 |

256 410 |

0.340 0.585 0.855 |

| 1 | CEW56-19 CEW56-20 CEW56-21 |

0 1 2 |

32.5 34.0 35.5 |

25.4 | 65 | 150 | 3 50 80 |

5 75 120 |

200 320 |

0.460 0.735 1.035 |

| 1 ¼ | CEW56-22 CEW56-23 CEW56-24 |

0 1 2 |

41.2 43.4 44.5 |

34.3 | 75 | 230 | 2 40 64 |

3 60 96 |

160 256 |

0.590 0.992 1.426 |

| 1 ½ | CEW56-25 CEW56-26 CEW56-27 |

0 1 2 |

49.9 51.7 53.8 |

40.1 | 90 | 240 | 1 35 54 |

2 53 84 |

140 224 |

0.865 1.355 1.877 |

| 2 | CEW56-28 CEW56-29 CEW56-30 |

0 1 2 |

60.4 62.7 64.3 |

50.3 | 110 | 260 | 1 30 48 |

2 45 72 |

120 192 |

1.12 1.846 2.623 |

| 2 ½ | CEW56-31 CEW56-32 CEW56-33 |

0 1 2 |

81.0 83.0 85.0 |

65.6 | 150 | 350 | 1 24 38 |

1.5 36 58 |

40 96 154 |

1.300 2.220 3.186 |

| 3 | CEW56-34 CEW56-35 CEW56-36 |

0 1 2 |

95.0 97.0 99.0 |

80.3 | 190 | 425 | 0.6 18 29 |

0.9 27 43 |

35 72 115 |

1.38 3.436 3.542 |

| 4 | CEW56-37 CEW56-38 CEW56-39 |

0 1 2 |

117.0 119.0 122.0 |

100.8 | 240 | 525 | 0.5 16 26 |

0.75 24 38 |

28 64 102 |

1.655 3.255 4.920 |

| 5 | CEW56-40 CEW56-41 CEW56-42 |

0 1 2 |

150.0 152.5 155.0 |

125.4 | 320 | 640 | 0.3 14 22 |

0.8 21.0 34 |

25 56 90 |

3.35 5.570 7.880 |

| 6 | CEW56-43 CEW56-44 CEW56-45 |

0 1 2 |

175.0 177.5 180.0 |

150.8 | 375 | 750 | 0.3 10 16 |

0.45 15 24 |

22 40 64 |

3.950 6.435 9.020 |

| 8 | CEW56-46 CEW56-47 CEW56-48 |

0 1 2 |

225.0 228.0 231.0 |

197.0 | 490 | 950 | 0.3 8 13 |

0.5 12.0 19 |

18 32 51 |

5.300 9.600 14.070 |

| 10 | CEW56-49 CEW56-50 CEW56-51 |

0 1 2 |

278.0 281.5 285.0 |

250.4 | 610 | 1150 | 0.2 7.5 12 |

0.3 11 18 |

18 30 48 |

8.400 15.000 21.850 |

| 12 | CEW56-52 CEW56-53 CEW56-54 |

0 1 2 |

336.0 339.5 343.0 |

300.2 | 710 | 1375 | 0.2 6 9.5 |

0.3 9 14 |

16 24 38 |

12.800 20.200 27.822 |