Braiding Material :

SS304/304L/316/316L

Fluid compatibility :

Bitumen, Fats, Naphthol, Phenol, Mercury, Sulphur, Fatty, acids, Paraffin, Tar, Chlorophenol, Chocolate, Heavy fuel oil, Naphthalene, Explosive (TNT), Thermosetting Plastic, Dimethyl terephthalate (DMT), Synthetic resin, Organic liquefied materials, Phthalic acid, waxes and others

Industrial application :

Refineries, Chemical industries, Power plant, Steel plant & Pharmaceutical Industries, etc.

Features :

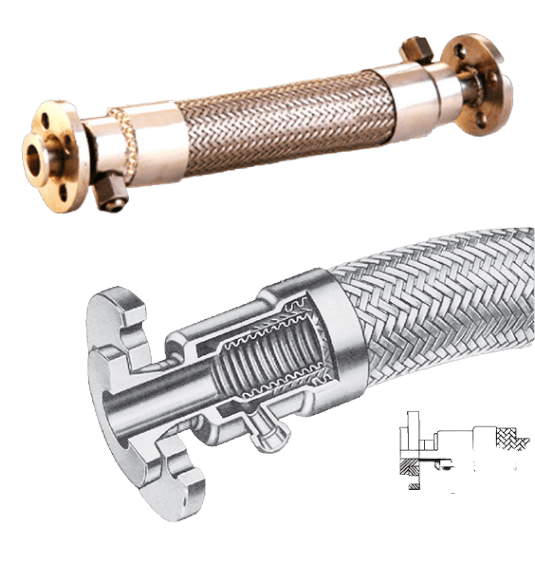

A Jacketed Hose assembly comprises a smaller "core hose" enclosed within a larger diameter hose. Specially designed fittings join the hoses at each end, ensuring no direct media pathway between them. These assemblies are commonly used when the primary media requires either elevated or cryogenic temperatures. Steam is often circulated through the jacket to maintain the temperature of viscous materials in the core hose or to insulate cryogenic liquids. The media transported can include steam, hot oil, hot water for heating purposes, or cold products like liquid helium or nitrogen for cooling applications.

Temperature :

400°C max. (600° C is possible as a special design)

| Core (Internal hose) |

Jacket tracer conduit

|

Threaded connection

(Pipe thread) inches |

|---|---|---|

| 10 | 25 | 3/8 |

| 16 | 32 | 3/8 |

| 20 | 40 | 1/2 |

| 25 | 50 | 1/2 |

| 32 | 50 | 1/2 |

| 40 | 65 | 1/2 |

| 50 | 80 | 3/4 |

| 65 | 100 | 3/4 |

| 80 | 125 | 3/4 |

| 100 | 150 | 3/4 |

| 125 | 175 | 1 |

| 150 | 200 | 1 |

| 200 | 250 | 1 |